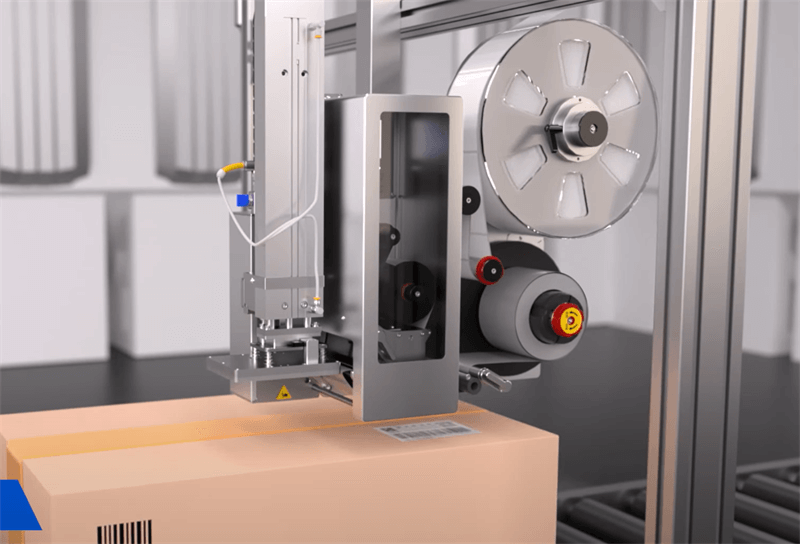

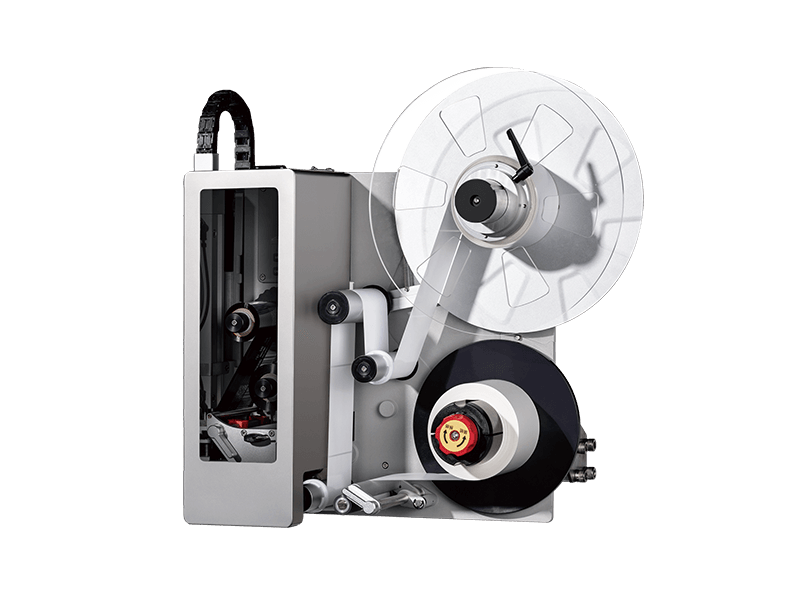

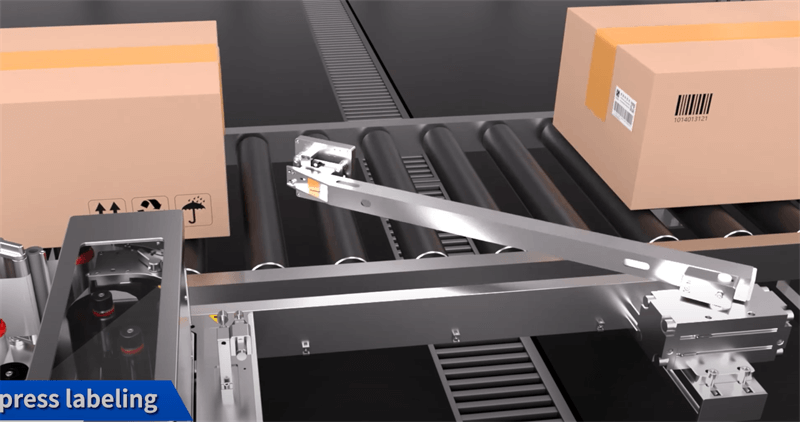

Bijvoorbeeld de iDPRT PA4 Afdrukken en toepassen van label applicator biedt ±1 mm nauwkeurigheid, dubbele thermische overdracht/directe thermische modi en 203, 300 of 600 dpi resolutie, met labels tot 6 inch breed.

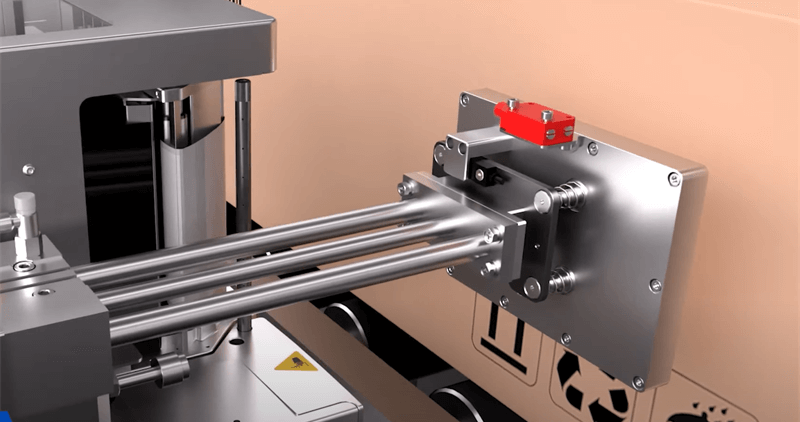

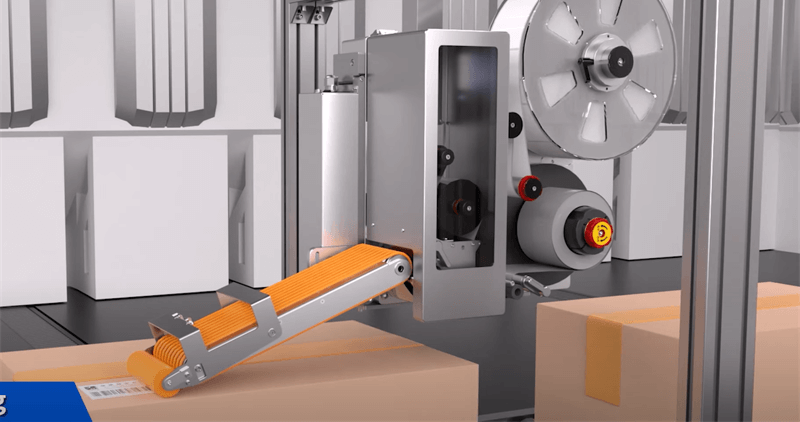

De PA4 werkt met een verscheidenheid aan 1D/2D barcodes, RFID-tags en labelmaterialen, waaronder linerless labels. Het biedt ook meerdere interfaces en printertaalopties, samen met aanpasbare applicatorarmen. Deze automatische pallet- en kartonlabelapplicator levert efficiënte, stabiele prestaties - perfect voor inkomende, uitgaande en trackingtaken - en voltooit de etikettering van het magazijn in één naadloos proces.